Travel

| X / Y / Z travel |

1,300/700/700 (51.1/27.5/27.5 Inch) mm |

| Spindle nose to table surface |

BT40:130~830 (5.1~32.6 Inch) mm

BT50: 100~800 (3.9~31.4 Inch) mm |

| Spindle center to column surface |

770 (30.3 Inch) mm |

Table

| Table size |

1,450x700 (57x27.5 Inch) mm |

| T slot ( Size / Qty / Dist. ) |

18x5x125 mm |

| Max. table load |

1,000 Kgs |

Spindle

| Speed |

BT40:8,000 rpm

BT50:8,000 rpm |

| Taper |

BT40/BT50 |

| Transmission |

Belt |

Feed Rate

| Rapid feed rate of XYZ |

30/30/24 M / min |

| Cutting feed rate |

1~12 M / min |

Automatic Tool Changer

| Tool storage capacity |

Arm type 24 tools |

| Max. tool diameter |

BT40 Full:80 mm Next empty:150 mm

BT50 Full:125 mm Next empty:150 mm |

| Max. tool length |

BT40:200 mm

BT50:300 mm |

| Max. tool weight |

BT40:7Kgs

BT50:15 Kgs |

CNC Controller & Motor

| CNC controller |

MITSUBISHI (*FANUC/SIEMENS/HEIDENHAIN) |

| Spindle motor |

7.5/11 kw (15 HP) |

Coolant

| Coolant pump |

1 HP |

| Coolant tank capacity |

400 L |

Air & Power Supply

| Air source |

6 Kg / c㎡ |

| Power supply |

12 KVA |

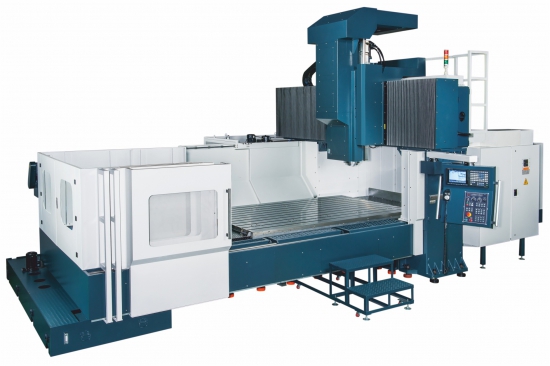

Machine Dimension

| Dimension |

3,650x2,915x3,027 mm |

| Net weight |

7,000 kgs |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine. Specifications are subject to change without notice.

Online Yedek Parça

Online Yedek Parça